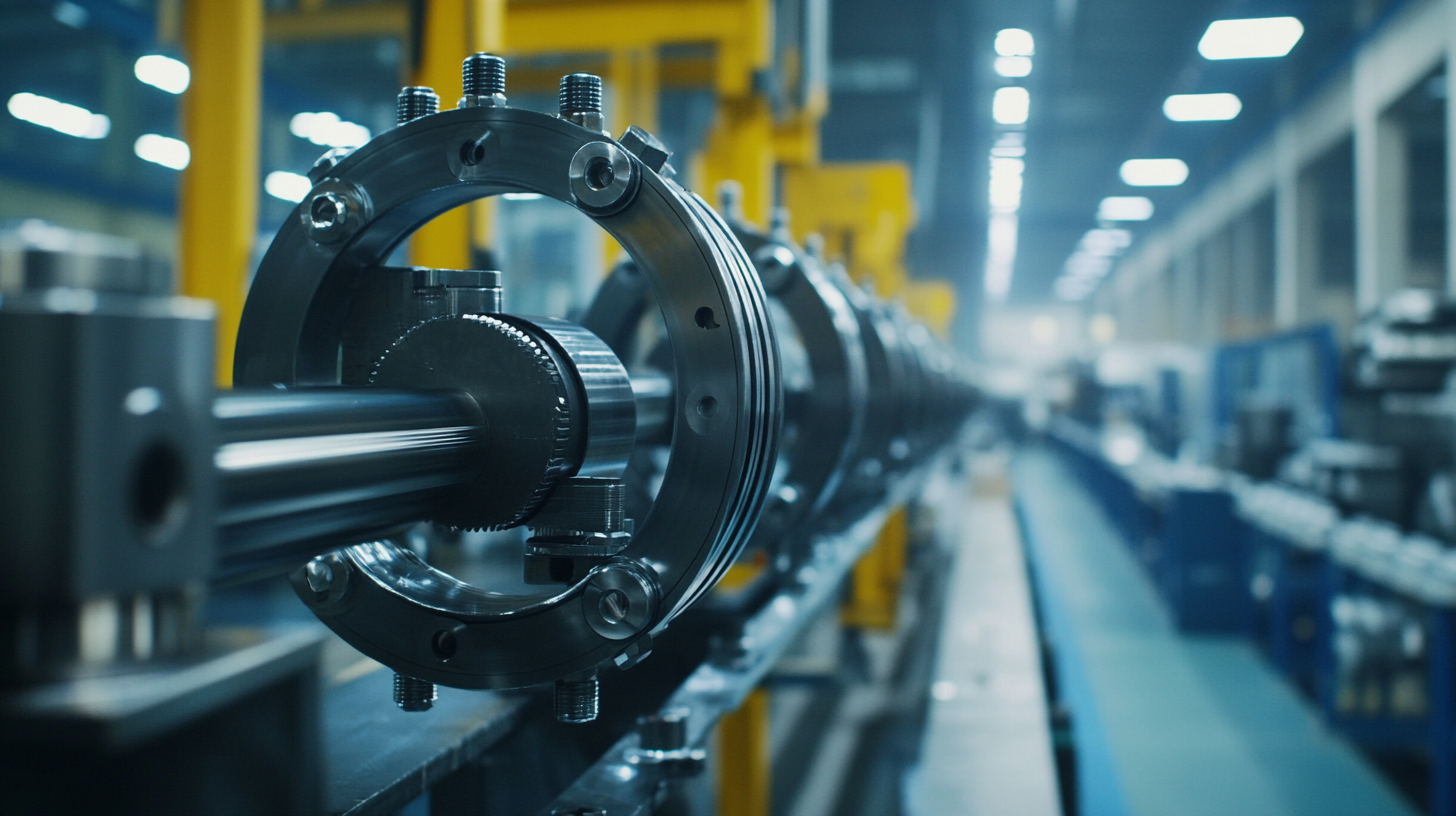

As the demand for efficiency and reliability in industrial processes continues to grow, China has emerged as a global leader in the production of industrial valves, blending innovation with unparalleled quality. Industrial valves play a crucial role in controlling the flow of liquids and gases in various sectors, including oil and gas, water treatment, and manufacturing. China's commitment to research and development has led to significant advancements in valve technology, ensuring that they meet the stringent requirements of modern industries. This blog will explore how Chinese manufacturers are pushing the boundaries of design and functionality in industrial valves, their impact on the global market, and the factors contributing to their leading position in innovation and quality. Through an in-depth analysis, we aim to showcase the remarkable transformations within this vital sector and the implications for businesses worldwide.

China has firmly established itself as a dominant force in the global industrial valve market, leading in both production capacity and innovative technology. The nation's industrial valve manufacturers are leveraging advanced manufacturing techniques and stringent quality control measures to produce a wide array of valves that meet international standards. This commitment to excellence has not only boosted China's export figures but also attracted foreign investments, solidifying its position in the competitive landscape.

Moreover, China's focus on research and development has enabled its companies to stay ahead of the curve in terms of innovation. By integrating smart technologies and automation into valve design and production, Chinese manufacturers are creating products that offer enhanced performance and reliability. This technological edge allows them to cater to various industries, including oil and gas, water treatment, and chemical processing, ensuring they meet the evolving demands of a global market increasingly focused on sustainability and efficiency. As a result, China's industrial valve sector is not only a crucial player in manufacturing but also a pivotal contributor to the global energy transition and infrastructure development.

China has emerged as a global leader in industrial valve production, setting benchmarks in both innovation and quality. The sector has seen significant technological advancements, driven by a commitment to research and development. The implementation of artificial intelligence and automation in manufacturing processes has not only enhanced efficiency but also improved precision in valve manufacturing. These state-of-the-art techniques allow for the production of valves that meet stringent international standards, catering to various industries from oil and gas to water treatment.

Tip: Companies looking to adopt these advancements can benefit from collaborating with Chinese manufacturers to leverage cutting-edge technologies. This partnership can lead to improved product designs and faster time-to-market solutions.

Furthermore, the focus on sustainable practices is reshaping the valve industry. Eco-friendly materials and energy-efficient production methods are becoming standard, which not only reduces environmental impact but also resonates with the growing demand for sustainability in industrial operations.

Tip: When considering suppliers, prioritize those who demonstrate a commitment to green manufacturing practices to align with global sustainability goals and enhance your brand’s reputation.

China's industrial valve production has truly revolutionized the global market, thanks in large part to its meticulous quality control standards. According to a recent report by MarketsandMarkets, the global industrial valves market was valued at approximately $70.6 billion in 2020 and is projected to reach $90.8 billion by 2025, with China leading the way in both production and innovation. This emphasis on quality is not merely a superficial trend; Chinese manufacturers have implemented stringent quality control processes, ensuring that their products comply with international standards such as ISO 9001 and API 6D.

Tips for enhancing quality control in valve production can include conducting regular audits and utilizing advanced technologies like AI and machine learning. This not only boosts production efficiency but also allows manufacturers to identify defects early in the manufacturing process, significantly reducing waste and cost. Moreover, fostering a culture of continuous improvement within the organization encourages employees to contribute ideas for enhancing quality.

Another significant factor setting China apart is the integration of new materials and technologies into valve production. With the rise of smart manufacturing and the adoption of IIoT (Industrial Internet of Things), Chinese manufacturers are at the forefront of developing resilient valves that meet the demanding needs of various industries. Investing in R&D and collaborating with international partners can further elevate these standards, contributing to the global competitiveness of Chinese industrial valves.

| Feature | China's Standard | Global Standard | Innovation Level |

|---|---|---|---|

| Material Quality | ASTM, DIN | ASTM, API | High |

| Manufacturing Process | CNC, Laser Cutting | CNC, Forging | Advanced |

| Testing Method | Hydraulic, Ultrasonic | Hydraulic, X-ray | Robust |

| Durability | 10+ Years | 5-10 Years | High |

| Environmental Standards | ISO 14001 | ISO 14001 | Commitment to Sustainability |

In recent years, the Chinese industrial valve manufacturing sector has made significant strides in efficiency, largely driven by advancements in automation technology. According to a report by ResearchAndMarkets, the global industrial valve market is projected to reach $100 billion by 2026, with a substantial share of this growth attributed to countries leading in automation, such as China. The integration of robotic systems in production lines has notably reduced lead times by up to 40%, allowing manufacturers to respond more rapidly to market demands.

Moreover, the implementation of Industry 4.0 principles has transformed traditional manufacturing processes into smart operations. With the use of IoT technology and data analytics, companies can monitor valve production in real-time, enhancing quality control while minimizing waste. A study from MarketsandMarkets indicates that the adoption of smart manufacturing technologies could save the valve industry approximately $30 billion annually by optimizing resource usage and improving operational uptime. This commitment to automation not only boosts production efficiency but also positions China's industrial valves as a benchmark in innovation and quality on the global stage.

China's industrial valve sector has witnessed remarkable advancements, showcasing innovation and quality that set a global benchmark. One standout example is the story of a leading Chinese valve manufacturer that embraced cutting-edge technology, such as smart manufacturing and automated testing. This company's commitment to R&D has led to the creation of valves that not only meet international standards but also exceed performance expectations in various sectors, including oil and gas, power generation, and water management.

Another compelling case is a small enterprise that revolutionized the market with a pioneering approach to sustainable valve solutions. By utilizing eco-friendly materials and processes, this company not only reduced its carbon footprint but also captured a significant share of the international market. Their success demonstrates how Chinese valve enterprises are not just meeting existing demands but are also proactively shaping the future of the industry through innovative practices and sustainable development.