In today's global market, the demand for reliable water mixing valves has surged due to an increased focus on energy efficiency and water conservation. According to a report by the Global Market Insights, the water mixing valve industry is projected to exceed USD 2.5 billion by 2025, indicating a growing recognition of the need for quality water control solutions. These essential components not only ensure consistent water temperatures but also enhance safety and comfort in residential and industrial applications. As the phrase "中国制造,全球共享,品质值得信赖" suggests, Chinese manufacturing plays a pivotal role in this market, offering products that meet international standards. When selecting the best water mixing valve, it is crucial to consider factors such as material durability, flow rate, and certification standards to ensure optimal performance and reliability in your water systems.

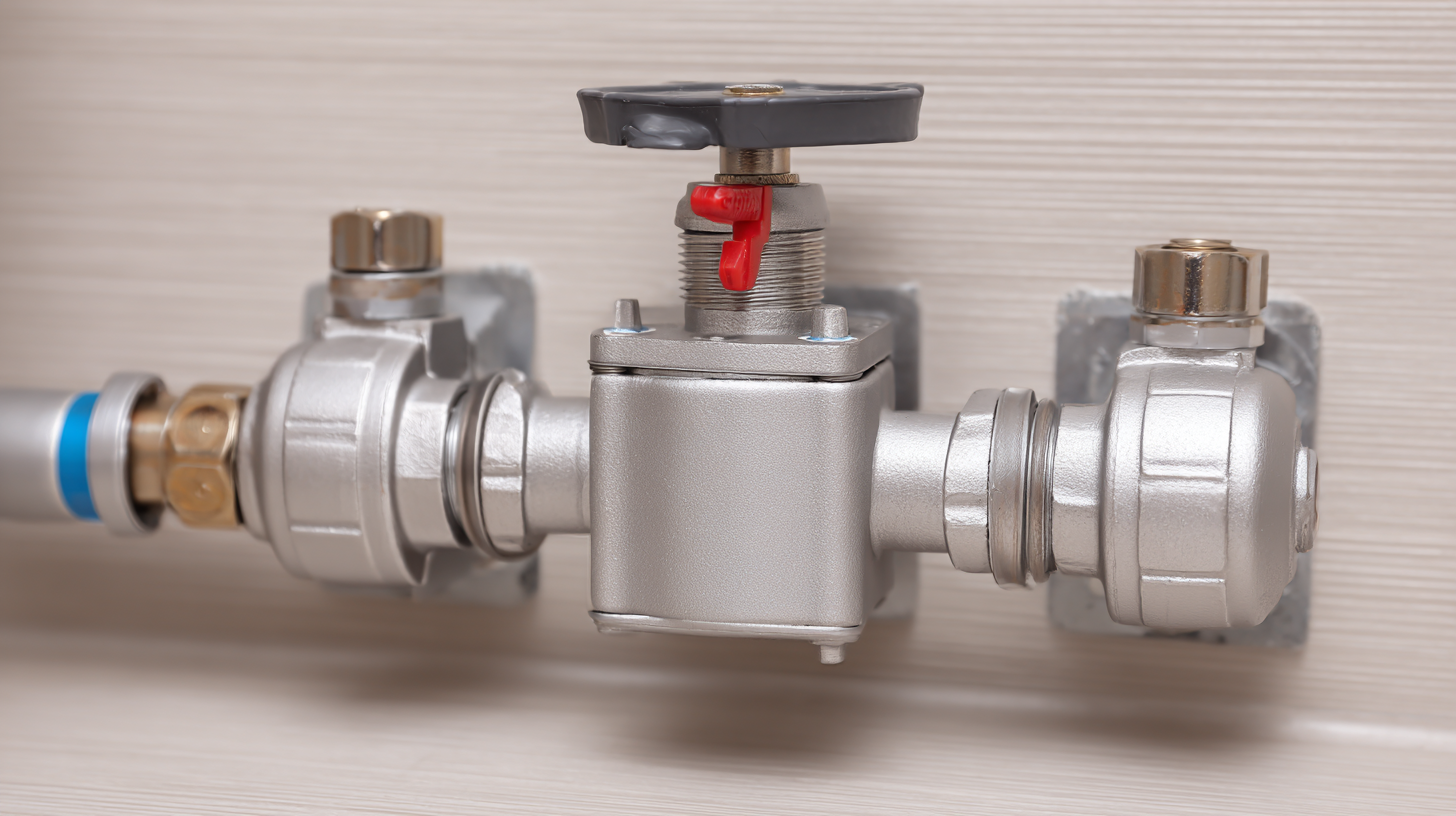

Water mixing valves play a crucial role in maintaining the ideal temperature of water in various applications, ranging from showers to industrial processes. These valves function by blending hot and cold water, ensuring a stable and safe output temperature. Understanding the mechanics behind these valves can greatly aid in selecting the right model for specific needs. The primary goal of a water mixing valve is to prevent scalding while providing optimal comfort, which is particularly important in residential plumbing systems.

Additionally, it’s essential to consider the compatibility of the valve with your existing plumbing systems. Different valves operate based on distinct mechanisms—thermostatic, pressure-balanced, or manual—that cater to various requirements. For instance, thermostatic mixing valves are excellent for maintaining consistent temperatures, making them ideal for homes with children or elderly residents. On the other hand, pressure-balanced valves adjust to changes in water pressure to prevent sudden temperature fluctuations. Therefore, understanding these functionalities not only helps in choosing the best water mixing valve but also enhances the overall safety and efficiency of your water systems.

When selecting a high-quality water mixing valve, it's crucial to focus on specific features that ensure optimal performance and durability. One of the key aspects to consider is the valve material. Look for valves made from robust materials such as brass or stainless steel, as these not only withstand high pressure and temperature but also provide a longer lifespan. A durable valve will not only enhance efficiency but also reduce the risk of leaks and failures.

Another important feature is the flow rate control. A good mixing valve should allow for precise adjustments to maintain the desired temperature in various applications. Check for valves with a quick-response mechanism to ensure consistent performance even with fluctuating water supply conditions. Additionally, consider models equipped with intelligent temperature control technology, which can significantly improve comfort and safety in daily use.

Finally, ease of installation and maintenance is vital. Opt for valves that come with user-friendly instructions and necessary fittings to streamline the setup process. Regular maintenance should also be manageable, so choose a design that allows for easy access to internal components without the need for specialized tools. These features collectively ensure that you choose the best valve for your needs.

When selecting the best water mixing valve for your needs, understanding the various manufacturers and their products is crucial. A comparative analysis of leading water mixing valve manufacturers reveals several key factors to consider: performance, durability, and technology innovations. Companies are increasingly focusing on the integration of advanced materials and designs to enhance mixing efficiency and reduce maintenance costs. This is particularly relevant in applications that require precise temperature and flow management, as evidenced by recent studies on emulsification techniques that improve fuel performance and reduce emissions.

The ongoing research into water and glycerin emulsification also underscores the importance of effective mixing in improving environmental outcomes. Similar principles apply to water mixing valves, where optimizing fluid dynamics can lead to significant energy savings and reduced operational impacts.

By evaluating different manufacturers on metrics like combustion characteristics and heat exchange efficiency in other fluid systems, potential buyers can make informed decisions that align with both performance needs and sustainability goals.

When selecting the best water mixing valve, evaluating durability and performance is crucial. Water mixing valves are essential in delivering consistent water temperature and quality, particularly in systems where water quality can be compromised by various environmental factors. Research indicates that the longevity of valves can be significantly affected by their material composition and susceptibility to corrosion. For instance, certain models utilize advanced materials capable of withstanding harsh conditions, thereby ensuring consistent performance over time.

In a recent meta-analysis on building water systems, it was found that interventions designed to address pathogens and chemical contaminants can improve overall water quality, indirectly highlighting the need for durable mixing valves that support these interventions. According to the study, water systems with newer technologies exhibit lower rates of microbial contamination and enhanced structural integrity, correlating with a decrease in chemical leaching and other quality concerns. Therefore, when assessing water mixing valves, it is essential to consider not only their operational efficiency but also how they can contribute to the maintenance of water quality in challenging environments.

| Tip | Description | Durability Factors | Performance Metrics |

|---|---|---|---|

| Material Selection | Choose materials that resist corrosion and are suitable for the intended water type. | Stainless Steel, Brass, Plastic | Lifespan, Resistance to Wear |

| Valve Type | Consider different types like thermostatic, pressure reducing, and manual valves. | Functionality under Pressure | Response Time, Mixing Efficiency |

| Flow Rate | Ensure the valve can handle the required flow rate for your system. | Maximum Flow Capacity | Pressure Drop, Operation Speed |

| Temperature Tolerance | Select valves that can operate within the temperature range of your application. | Thermal Stability | Effective Range, Performance at Extremes |

| Installation Flexibility | Check whether the valve can be installed in various orientations and positions. | Compatibility with Plumbing System | Ease of Maintenance, Serviceability |

| Regulatory Compliance | Ensure the valve meets industry standards and regulations for safety and performance. | Certifications, Material Standards | Quality Assurance, Reliability |

| Warranty and Support | Look for products with a strong warranty and customer support. | Manufacturer Reputation | Post-sale Service, Return Policies |

When selecting a water mixing valve, understanding the importance of certifications and standards is crucial to ensure reliability and safety in plumbing systems. For instance, potable water fittings, including valves, must meet NSF/ANSI 61 standards, which assess the health effects of materials in contact with drinking water. This certification process includes rigorous testing of valve samples to ensure they do not leach harmful contaminants, making it a vital consideration for any installation.

In addition to potable water standards, the significance of certifications such as Safety Integrity Level (SIL) for valve actuators must not be overlooked. SIL certification ensures that the valve actuators perform reliably, reducing the risk of system failures that could lead to operational hazards. With the increasing adoption of advanced technologies in the HVAC industry, such as variable refrigerant flow (VRF) systems, the demand for validated and certified components is on the rise. A report indicates that uncertified systems may compromise efficiency and safety, reinforcing the need for adherence to established standards. By prioritizing certified products, engineers can enhance system performance and ensure compliance with regulatory requirements.