In the ever-evolving landscape of plumbing solutions, understanding the various types of Thermostatic Mixing Valves (TMVs) becomes crucial for global buyers seeking efficiency and safety in their systems. According to a recent report from the International Association of Plumbing and Mechanical Officials (IAPMO), the market for TMVs is projected to grow significantly, driven by increasing awareness of water safety and energy conservation practices. TMVs play a vital role in controlling water temperatures, thus preventing scalding while enhancing user comfort. As the demand for sustainable and reliable water management systems rises, knowing the key differences among the various types of TMVs, such as their design, application, and operational benefits, will empower buyers to make informed decisions that align with their specific requirements and regulatory standards.

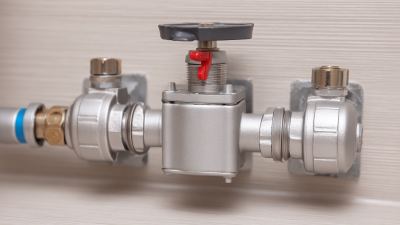

Thermostatic mixing valves (TMVs) are essential components in plumbing systems, designed to blend hot and cold water to ensure a safe and consistent temperature at the outlet. Buyers globally must understand the key features distinguishing different types of TMVs, as these differences can significantly impact their performance and reliability in various applications.

For instance, adjustable TMVs allow users to customize water temperature settings, making them ideal for residential use where individual preferences vary. On the other hand, pre-set TMVs are often used in commercial settings, where a standardized temperature is required to meet safety regulations.

According to a recent market report, the global thermostatic mixing valve market is projected to grow from USD 1,315 million in 2025 to USD 1,984 million by 2035, reflecting a compound annual growth rate (CAGR) of 4.2%. This growth is driven by increasing awareness of water safety and efficiency, urging global buyers to invest in advanced TMVs. Moreover, features such as automatic shut-off mechanisms and anti-scald functionality are becoming increasingly popular, as they enhance safety measures in domestic and commercial environments.

Understanding these key features not only aids buyers in making informed decisions but also highlights the ongoing innovations within the TMV market to address evolving consumer needs.

When it comes to selecting thermostatic mixing valves, global buyers often face the choice between brass and plastic varieties. Brass thermostatic mixing valves are renowned for their durability and resistance to corrosion, making them ideal for high-pressure environments and long-term usage. Their robust construction also enables them to withstand fluctuations in temperature and pressure, ensuring a reliable performance. However, they tend to be heavier and more expensive than their plastic counterparts, which may be a consideration for some buyers.

On the other hand, plastic thermostatic mixing valves present an appealing alternative, particularly for projects focused on cost efficiency and weight reduction. These valves are typically lighter and less expensive, making them a popular choice for residential applications and smaller-scale installations. While they may not match the longevity of brass valves, advances in materials and technology have significantly improved their performance, allowing them to serve effectively in environments with lower temperature and pressure demands. As the thermostatic mixing valve market is projected to reach $1.98 billion by 2035, driven by safety regulations and energy efficiency trends, understanding the comparative features of brass and plastic options is essential for informed purchasing decisions.

When it comes to selecting the right thermostatic mixing valve (TMV) for specific applications, understanding the differences between valve types is crucial for global buyers. TMVs are commonly used in domestic water systems, commercial buildings, and healthcare facilities. According to a recent report by ResearchAndMarkets, the global TMV market is projected to reach $1.64 billion by 2027, with increasing demand driven by safety regulations and energy efficiency needs.

In residential settings, pressure-balanced TMVs are often favored for their ability to maintain a safe outlet temperature, especially in showers and bathtubs. This feature is crucial in preventing scalding accidents, particularly for vulnerable populations such as children and the elderly. On the other hand, in commercial applications, such as hospitals and nursing homes, thermostatic mixing valves designed for higher flow rates would be ideal. These valves not only ensure consistent water temperatures for patient safety but also comply with stringent health regulations, as highlighted in a report by the International Code Council.

Each type of TMV plays a vital role in different environments. For example, anti-scald TMVs are increasingly used in educational institutions where children are present, while industrial applications often favor thermostatic valves that can handle larger water volumes and varying pressures. With the ongoing emphasis on building safety and energy conservation, the proper understanding and application of TMV types will remain paramount for global buyers in the construction and plumbing industries.

When installing a thermostatic mixing valve (TMV),

it’s essential to follow best practices to ensure optimal performance

and safety. First, proper positioning is crucial; TMVs should be installed close to the outlets they serve to

minimize the risk of temperature fluctuations. This proximity allows for real-time adjustments to water

temperatures, ensuring comfort and preventing scalding, particularly in residential and healthcare settings.

Another key aspect of installation is ensuring correct pipe sizing and layout. The inlet piping should be sized

according to the manufacturer’s specifications to avoid excessive pressure drops.

Additionally, using insulated pipes can help maintain the water temperature

and enhance the efficiency of the valve. Regular maintenance checks are also recommended to confirm that the valve

functions correctly over time, including inspecting for any scale buildup or other obstructions that might affect performance.

By adhering to these best practices, users can maximize the efficiency

and lifespan of their thermostatic mixing valves, making sure they operate seamlessly in various applications.

When it comes to the upkeep of thermostatic mixing valves (TMVs), understanding maintenance considerations is essential for ensuring their longevity and optimal performance. Regular maintenance of TMVs not only enhances their lifespan but also contributes to safety and comfort in both residential and commercial settings. According to industry standards, regular checks and cleaning are recommended every six months, as this can prevent issues such as mineral buildup and internal corrosion, which are common in environments with hard water.

Moreover, the demand for TMVs is increasingly influenced by sustainability trends, particularly in light of recent developments aimed at achieving Net Zero targets. Implementing low temperature heating solutions can significantly reduce energy consumption while ensuring that water delivery systems remain efficient. Investing in high-quality TMVs tailored for specific applications, like those specified under the NDIS Specialist Disability Accommodation standards, can further enhance accessibility, showcasing the importance of thoughtful design in meeting diverse needs. Regular maintenance of these valves ensures they function effectively, providing a safe and controlled water temperature essential for vulnerable users.