In the quest for optimal industrial efficiency, selecting the right Flow Control Valve is paramount. According to a recent report by the Global Flow Control Valve Market Research Institute, the flow control valve market is projected to reach $8 billion by 2027, driven by the increasing demand for advanced automation and process control across various industries.

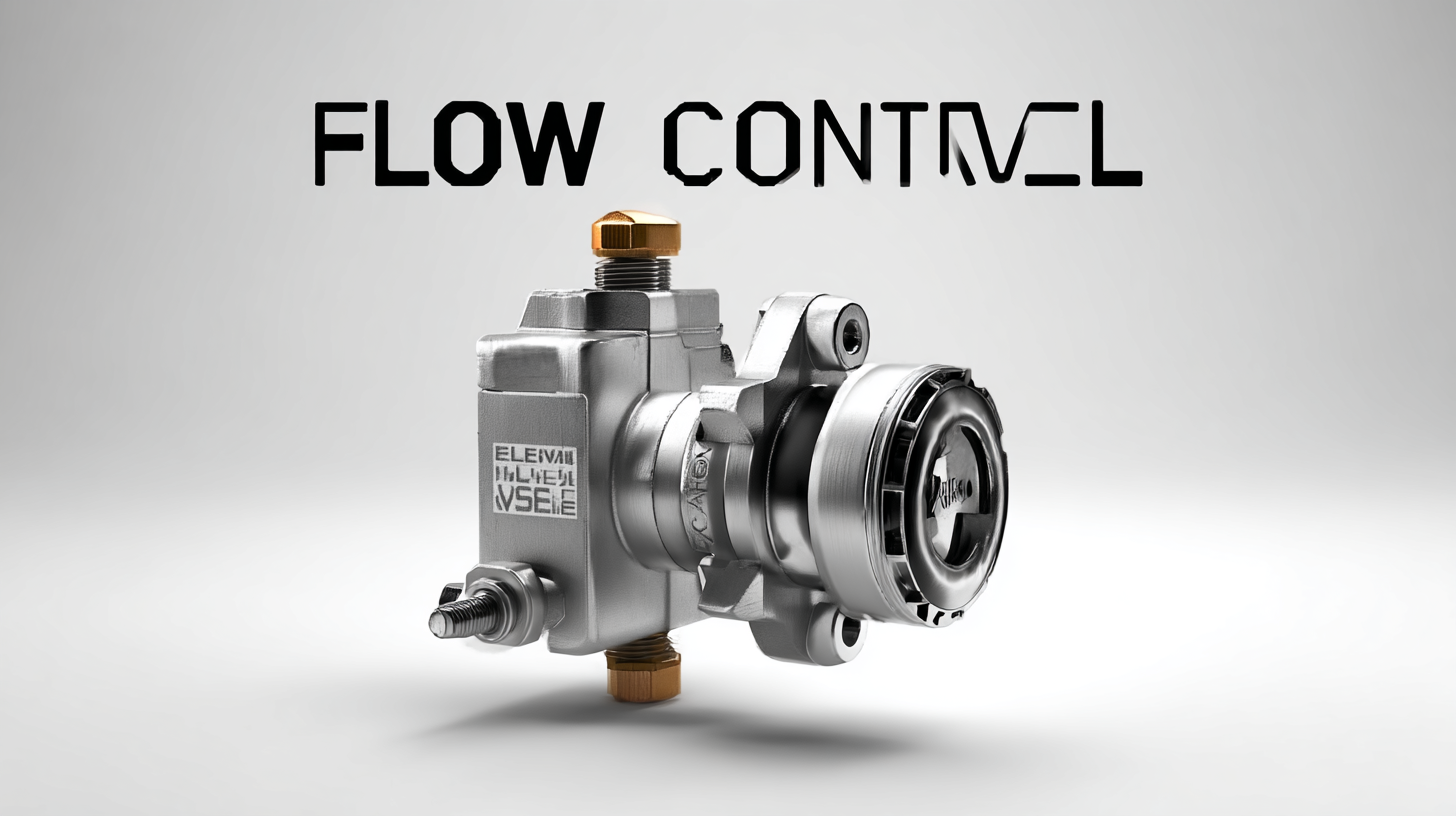

Flow control valves are critical components in fluid management systems, influencing the overall performance and efficiency of industrial operations. A data-driven approach to selecting these valves not only enhances operational effectiveness but also mitigates energy consumption, as improperly configured valves can lead to significant waste.

Therefore, understanding the specifics of flow control valves, coupled with empirical data on their performance and application, is essential for industries aiming to thrive in a competitive landscape.

Flow control valves are critical components in fluid management systems, influencing the overall performance and efficiency of industrial operations. A data-driven approach to selecting these valves not only enhances operational effectiveness but also mitigates energy consumption, as improperly configured valves can lead to significant waste.

Therefore, understanding the specifics of flow control valves, coupled with empirical data on their performance and application, is essential for industries aiming to thrive in a competitive landscape.

Flow control valves play a crucial role in maintaining optimal conditions within industrial systems, ensuring efficiency and sustainability. There are several types of flow control valves, including globe, ball, and gate valves, each designed for specific applications. According to a report by Technavio, the global industrial valve market is expected to grow by approximately $8 billion from 2021 to 2025, underscoring the increasing recognition of these components in enhancing operational efficiency.

In terms of applications, flow control valves are widely utilized in industries such as oil and gas, water and wastewater, and manufacturing. For instance, a study by Grand View Research highlights that the oil and gas sector accounts for over 40% of the industrial valve market share. This segment particularly benefits from specialized flow control solutions that ensure accurate flow measurement and regulation, which are essential for maintaining safety and cost-effectiveness throughout processes. By selecting the right type of flow control valve tailored to their specific operational needs, industries can significantly improve their overall performance and reduce wastage, ultimately contributing to better resource management and sustainability.

When selecting flow control valves for industrial applications, several key factors must be considered to ensure optimal efficiency. One critical aspect is the valve type, as different applications may require varying flow characteristics. For instance, a report from the International Society of Automation indicates that globe valves are preferred for precision flow control, while ball valves are ideal for on/off applications due to their quick operation and lower pressure drop.

Another significant factor is the valve size and material, which directly affect the flow capacity and durability in various environments. According to the Flow Control Valve Market Report 2023, improper sizing can lead to energy losses of up to 30%, underscoring the importance of accurate calculations based on the specific application requirements. Additionally, the choice of materials like stainless steel or brass can influence the longevity of the valve and its resistance to corrosive substances, thereby impacting maintenance costs and system reliability.

Finally, understanding the specific operational conditions, such as temperature and pressure ranges, is paramount. A study published by the American Society of Mechanical Engineers (ASME) highlights that valves operating outside their specified parameters can experience significant wear, resulting in increased downtime and operational inefficiencies. Therefore, careful evaluation of these factors can lead to better decision-making and improved industrial performance.

In the quest for optimal industrial efficiency, the selection of flow control valves plays a crucial role. By employing data analytics to enhance valve selection criteria, companies can significantly improve operational performance and reduce costs. According to a recent study by the Flow Control Institute, utilizing predictive analytics in valve selection can lead to a 15-20% reduction in energy use, highlighting the importance of a data-driven approach.

When selecting the best flow control valve, consider integrating key performance indicators (KPIs) such as flow rate, pressure drop, and response time. Data insights reveal that valves with optimized performance characteristics can enhance system reliability, leading to decreased maintenance costs. For instance, a report from the International Society of Automation found that smart valve technologies can extend service life by up to 30%, minimizing overall downtime.

Tip: Leverage software tools that analyze historical process data to predict future valve performance under varying operational conditions.

Tip: Regularly review and update your valve specifications based on the latest performance data to ensure alignment with evolving industrial standards. Utilizing these data-driven strategies will empower organizations to make informed decisions, ultimately resulting in enhanced efficiency and reduced operational costs.

Testing and validating flow control valve performance is essential for optimizing industrial efficiency. Recent studies have shown how variations in design can significantly impact performance. For instance, the full linearization of nonlinear flow control valves using variable gear ratio design demonstrated improvements in responsiveness and accuracy, which are critical for precise control in various applications.

This approach ensures that manufacturers can maintain high efficiency levels by enabling better performance tracking and adjustments based on real-time data.

Furthermore, the performance analysis of control valves in innovative cooling systems, such as solar-driven adsorption chillers, revealed that regulating refrigerant flow efficiently enhances thermal energy storage. Reports indicate that effective management of refrigerant flow can lead to a reduction in energy consumption by up to 20%, showcasing the significant role of flow control valves in energy optimization.

As industries continue to evolve, the integration of advanced testing methods and validation strategies will remain crucial for ensuring that flow control valves meet the demands of modern applications.

Maintaining flow control valves is crucial for ensuring optimal industrial efficiency.

Regular inspection and maintenance practices can prevent unexpected failures and prolong the lifespan of these essential components.

To start, it’s vital to establish a routine maintenance schedule that aligns with the manufacturer’s recommendations and operational demands.

This encompasses visual inspections for leaks, wear, and corrosion, which can signal underlying issues.

Additionally, performing regular function tests can help identify deviations in performance, allowing for timely corrective actions.

Optimizing flow control valve performance involves keeping a close watch on the system’s operational parameters.

Utilizing data analytics can significantly enhance decision-making;

sensors and monitoring tools can provide real-time insights into flow rates, pressure changes, and temperature fluctuations.

By analyzing this data, operators can fine-tune valve settings, ensuring they respond accurately to varying process conditions.

Training personnel on best practices for valve operation and troubleshooting further empowers teams to manage systems efficiently,

fostering a culture of proactive maintenance that ultimately drives productivity and cost-effectiveness in industrial environments.