Selecting the appropriate Temperature Mixing Valve (TMV) is crucial for ensuring optimal performance in various applications, particularly in healthcare and residential settings. According to a report by the American Society of Plumbing Engineers, improper temperature control can lead to scalding risks, especially among vulnerable populations such as children and the elderly. In fact, studies indicate that scald injuries account for over 65% of burn-related incidents in young children, underscoring the importance of effective temperature regulation in plumbing systems.

Moreover, the global market for temperature mixing valves is projected to grow significantly, driven by increasing regulatory standards for safety and performance. As industry demands evolve, understanding the technical specifications and features of TMVs is essential for making informed decisions that align with safety, efficiency, and regulatory compliance. This guide aims to provide insights into selecting the right Temperature Mixing Valve to meet your specific needs and ensure peace of mind in your installations.

Selecting the appropriate Temperature Mixing Valve (TMV) is crucial for ensuring optimal performance in various applications, particularly in healthcare and residential settings. According to a report by the American Society of Plumbing Engineers, improper temperature control can lead to scalding risks, especially among vulnerable populations such as children and the elderly. In fact, studies indicate that scald injuries account for over 65% of burn-related incidents in young children, underscoring the importance of effective temperature regulation in plumbing systems.

Moreover, the global market for temperature mixing valves is projected to grow significantly, driven by increasing regulatory standards for safety and performance. As industry demands evolve, understanding the technical specifications and features of TMVs is essential for making informed decisions that align with safety, efficiency, and regulatory compliance. This guide aims to provide insights into selecting the right Temperature Mixing Valve to meet your specific needs and ensure peace of mind in your installations.

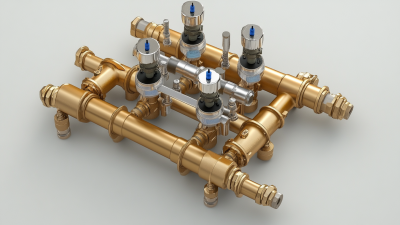

Thermostatic mixing valves (TMVs) play a crucial role in modern plumbing systems by ensuring water temperature is regulated safely and efficiently. These valves blend hot and cold water to deliver a consistent and comfortable temperature at outlets such as taps and showers, preventing both scalding and thermal shock. As the market for TMVs is projected to reach USD 1,749.6 million by 2032, the growing awareness of their functionality and benefits highlights their importance in residential and commercial settings.

The advantages of using TMVs extend beyond safety; they contribute significantly to energy efficiency. By maintaining optimal temperatures, TMVs can help reduce energy consumption, thus minimizing utility bills. They are particularly beneficial in homes with children or elderly residents, where the risk of burns is a serious concern. Additionally, innovations in valve technology, including more flexible designs, cater to the diverse needs of specifiers and contractors, offering greater customization and adaptability in various installations.

As the industry progresses, the importance of selecting the right TMV for specific requirements becomes increasingly evident, ensuring enhanced performance and safety.

When choosing a temperature mixing valve, it's essential to consider several key factors to ensure that you select the best option for your specific needs.

First, flow rate is a critical aspect; it determines how much water can pass through the valve without compromising performance.

According to a report by the American Society of Plumbing Engineers (ASPE), a flow rate that exceeds 2.5 gallons per minute may require a proportional valve to maintain steady temperatures and prevent fluctuations.

Another important factor to evaluate is the valve’s operational range. Mixing valves are designed to operate within specific temperature limits; for instance, some may effectively blend hot and cold water to a safe delivery temperature, typically between 120°F and 140°F.

Choosing a valve with an appropriate temperature range is vital for safety and efficiency, as underscores a recent study by the International Association of Plumbing and Mechanical Officials (IAPMO), which found that using the correct temperature settings can reduce the risk of scalding by nearly 50%.

Lastly, compatibility with existing plumbing systems must also be taken into account.

Many modern mixing valves are designed to integrate seamlessly with digital monitoring systems, enhancing user control and energy efficiency. According to the U.S. Department of Energy, integrating smart technology can save households up to 40% on water heating costs.

Therefore, evaluating compatibility with advanced systems can lead to improved performance and significant savings in the long run.

When selecting the right temperature mixing valve, understanding flow rates and pressure requirements is crucial for optimal performance. According to the American Society of Plumbing Engineers, maintaining a balance in flow rates often results in more efficient heating systems, which can save up to 15% on energy costs. Flow rates can vary based on the system type; for instance, residential applications typically require flow rates between 2 to 10 gallons per minute (GPM), while commercial systems may demand significantly higher rates.

When evaluating pressure requirements, it's essential to refer to the National Fire Protection Association guidelines, which suggest that pressure should be maintained within 20-80 psi for safe and effective operation. Analyzing the specific needs of your system will ensure longevity and reliability.

**Tips:** Always consult with a professional when determining the specific flow rates and pressure needed for your mixing valve installation. Regular maintenance checks can prevent pressure fluctuations that might lead to valve malfunction. Additionally, selecting valves with adjustable settings may offer greater flexibility in adapting to changing water supply conditions.

When selecting a temperature mixing valve, understanding the accuracy and control features is paramount. Accurate temperature control is essential to prevent issues like scalding, which remains a common problem in plumbing systems due to misconceptions around thermostat settings on traditional water heaters. An effective mixing valve should provide precise temperature regulation, mitigating risks and enhancing user safety.

In addition to accuracy, control features play a critical role in optimizing the performance of mixing valves. Modern smart radiator valves, for instance, enable individual room temperature management, allowing for programmable settings that adapt to user preferences. Furthermore, advancements in control strategies, such as model predictive control, leverage forecasts to enhance the responsiveness of temperature regulation. This integration of technology and control methodologies is vital in ensuring that mixing valves not only maintain desired temperatures but also support energy efficiency in dynamic environments.

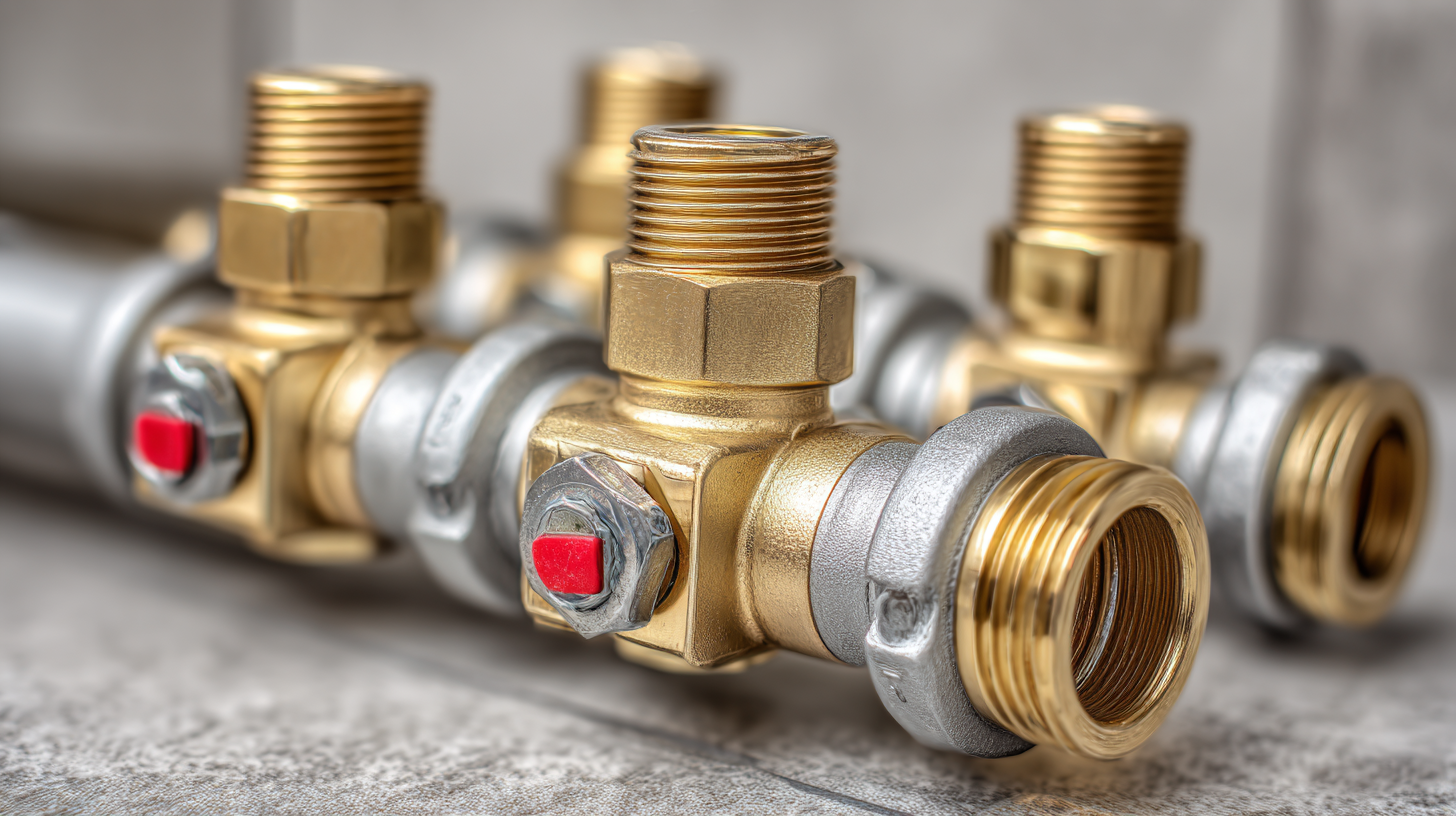

When selecting the appropriate temperature mixing valve for various applications, one crucial factor to consider is material compatibility. The longevity and safety of these valves depend significantly on the materials used. For instance, in systems involving hydrogen storage and transport, such as those utilizing liquid organic hydrogen carriers, selecting materials that can withstand high pressure and corrosive environments is essential to prevent breakdown and ensure effective operation.

Similarly, in medical applications, the compatibility of hemoperfusion adsorbents must be evaluated to improve blood compatibility, thereby enhancing patient safety during procedures. The materials used in these systems must not only resist chemical interactions but also provide a reliable interface between the device and biological elements. As industries increasingly turn to advanced technologies, the importance of selecting compatible materials extends to sectors like electric vehicle battery thermal management, where ensuring that heat dissipation systems interact safely with lithium-ion batteries is critical for performance and reliability. Therefore, extensive research and careful assessment of material properties are vital in achieving safe and durable mixing valves tailored to specific needs.