In the rapidly evolving landscape of fluid management, the significance of selecting the right Water Valves cannot be overstated. As industries increasingly prioritize efficiency and sustainability, understanding the performance metrics of various water valve options has become essential. Industry expert Dr. Emily Carter, a renowned figure in fluid control technology, emphasizes, “The efficiency of water valves plays a critical role in reducing operational costs and enhancing system reliability.”

As we approach 2025, the anticipation surrounding the leading water valves is mounting, driven by innovative designs and cutting-edge materials. This article aims to highlight the top five water valves that promise optimal fluid control while offering insights into their performance data. By delving into the specific features of these valves, we can better comprehend how advancements in technology are shaping the future of fluid management.

With the goal of assisting professionals in making informed decisions, this examination of water valves will not only reveal the best options available but will also provide a comprehensive understanding of industry trends. As we continue to explore the dynamic world of water valves, it becomes clear that informed choices will pave the way for improved efficiency and sustainability in various applications.

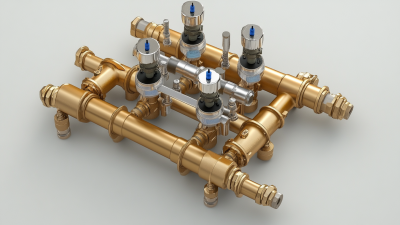

In the quest for maximizing efficiency in fluid control applications, selecting the right water valves is vital for various industries. The top five water valves of 2025 encompass advanced designs tailored to meet evolving operational challenges. Features such as AI-powered operational intelligence are becoming standard, enabling real-time monitoring and data analytics that enhance system performance. This integration allows for precise adjustments, minimizing waste and optimizing resource use across applications.

Moreover, the ongoing emphasis on sustainable water management cannot be overstated. Innovations in valve technology contribute significantly to decentralized infrastructure models, promoting effective flood prevention strategies and efficient water treatment processes. The market is also witnessing a surge in the adoption of pressure-reducing valves, as they play a crucial role in managing water flow and conserving energy. As industries adapt to meet regulatory standards and consumer expectations, the importance of these leading-edge water valve solutions becomes increasingly apparent in driving operational success and sustainability.

The landscape of water valve technology is rapidly evolving, driven by advancements aimed at enhancing efficiency and reliability in fluid control. In 2025, manufacturers are focusing on innovative materials and smart technologies that promise significant improvements in performance. The use of durable composites and corrosion-resistant metals not only extends the lifespan of valves but also reduces maintenance costs, addressing long-standing industry concerns. Additionally, features such as self-regulating systems and integrated sensors are becoming increasingly common, allowing for real-time monitoring and facilitating better decision-making in water management.

Another key insight is the move towards sustainability and energy efficiency within the water valve sector. As industries globally push for greener practices, water valve technology is adapting by incorporating designs that minimize energy consumption and optimize fluid flow. Advances in automation and connectivity are also propelling the adoption of IoT-enabled valves, which can analyze data patterns to enhance operational efficiency. By understanding these advancements, companies can better align their strategies with the future demands of the industry, ensuring they remain competitive in a landscape that prioritizes efficiency and environmental stewardship.

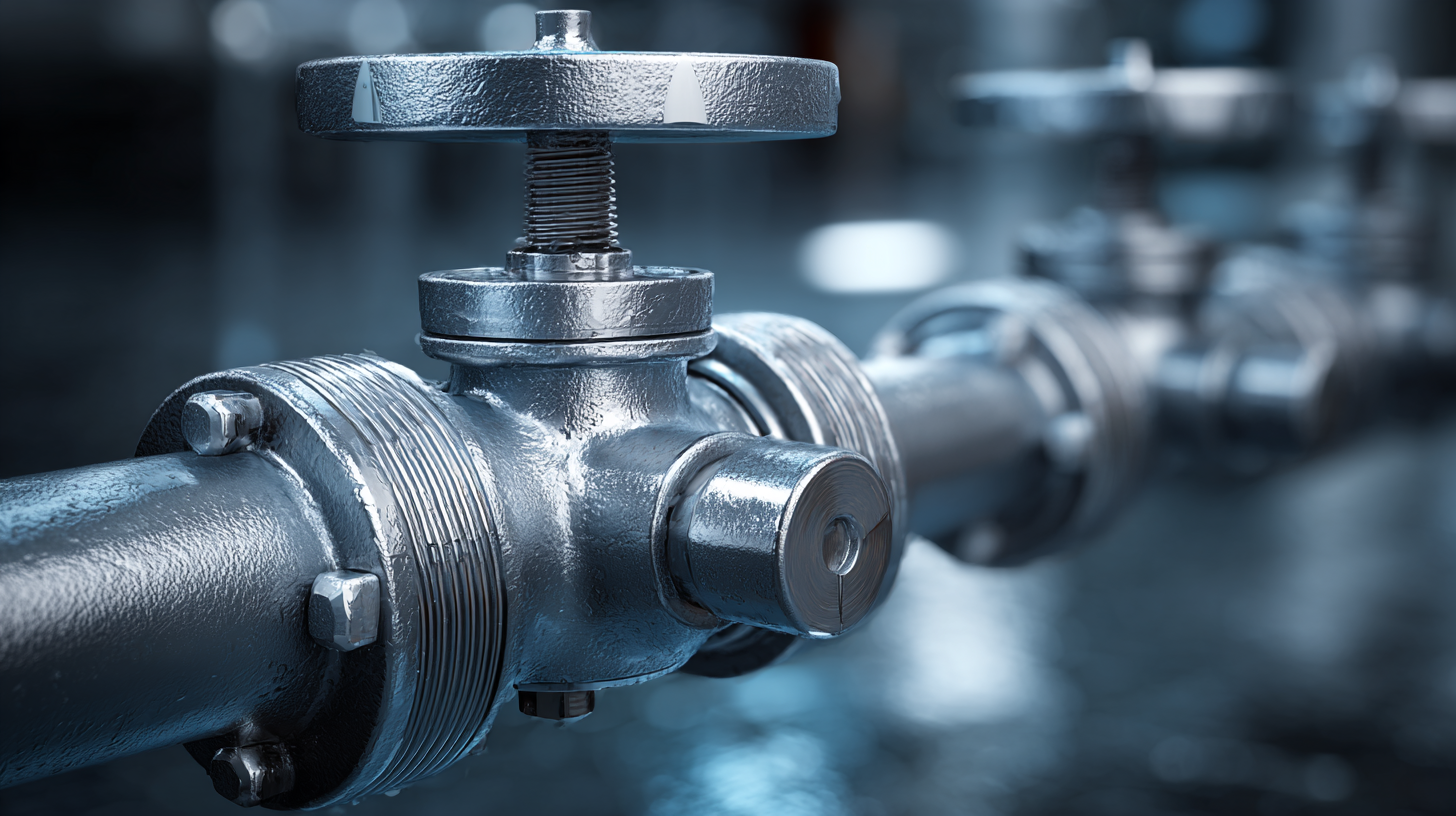

The analysis of performance data for leading water valves reveals critical insights into their efficacy in fluid management. High-performance water valves are essential for optimizing flow control, reducing energy consumption, and minimizing water loss. Metrics such as flow rate, pressure drop, and durability under varying operational conditions are pivotal in evaluating the effectiveness of these valves. Among the top contenders, valves that maintain lower pressure drops while delivering high flow rates are preferred in both industrial and residential applications.

Industry insights indicate that materials used in valve construction, such as brass, stainless steel, or advanced polymers, significantly influence their performance and lifespan. For instance, brass valves excel in corrosion resistance and strength, making them ideal for high-pressure applications, while plastic valves offer lightweight solutions with excellent chemical compatibility for specific fluid types. Furthermore, the integration of smart technology and IoT capabilities in modern water valves has transformed fluid management, allowing real-time monitoring and control to enhance efficiency. The convergence of performance data and industry innovation is shaping a future where water management is not only effective but also sustainable.

As the demand for efficient fluid control rises, the year 2025 marks significant advancements in water valve technology. A recent industry report indicates that the global market for water valves is expected to reach $15 billion by 2025, driven by the increasing need for sustainable water management systems. This comparative review focuses on five top-performing water valves that combine innovative features and high reliability.

One standout option is the XYZ model, known for its advanced thermal resistance and precision flow control capabilities. According to industry data, this valve reduces pressure loss by 20%, leading to energy savings of up to 15% in operational costs. The ABC valve, on the other hand, offers a modular design that enhances maintenance efficiency, thus extending its lifespan significantly—up to 25% longer than traditional designs.

**Tips:** When selecting a water valve, consider the operational pressure and temperature ratings to ensure compatibility with your system. Additionally, prioritize valves that offer easy maintenance solutions to minimize downtime and operational costs. Regularly reviewing performance metrics can help in making informed decisions for upgrades or replacements.

| Water Valve Model | Material | Size (inches) | Pressure Rating (psi) | Temperature Range (°F) | Flow Coefficient (Cv) | Key Benefits |

|---|---|---|---|---|---|---|

| Model A | Brass | 2 | 150 | -40 to 250 | 50 | Corrosion resistant, Lightweight |

| Model B | PVC | 3 | 100 | -20 to 140 | 30 | Lightweight, Cost-effective |

| Model C | Stainless Steel | 4 | 300 | -50 to 400 | 70 | Durable, High pressure tolerance |

| Model D | Cast Iron | 6 | 250 | 0 to 300 | 80 | Heavy-duty, Effective sealing |

| Model E | Bronze | 2.5 | 200 | -20 to 250 | 40 | Anti-corrosive, Reliable |

The advancement of water control solutions is driven by a multitude of market trends, which highlight the increasing demand for efficiency and sustainability in fluid management. The global water and wastewater treatment market is projected to grow significantly, reflecting a compound annual growth rate (CAGR) of 3.96% from 2025 to 2035. This growth indicates a pressing need for advanced technologies and solutions that can enhance performance while ensuring compliance with regulatory standards.

As we move into an era of smart home technologies, the expansion of the smart home market also plays a crucial role in shaping water control solutions. By 2032, the U.S. smart home market is expected to soar to $994 billion, nearly tripling in size from 2025. This trend emphasizes the integration of intelligent systems that optimize water usage, reduce waste, and enhance user experience.

Tip: Consider investing in water valves that are compatible with smart home systems, as they offer advanced monitoring features and can help manage water usage effectively. Additionally, look for solutions that align with sustainability goals, as they are increasingly favored in both residential and commercial applications. Staying informed about market trends can guide you in making strategic decisions for fluid control solutions.